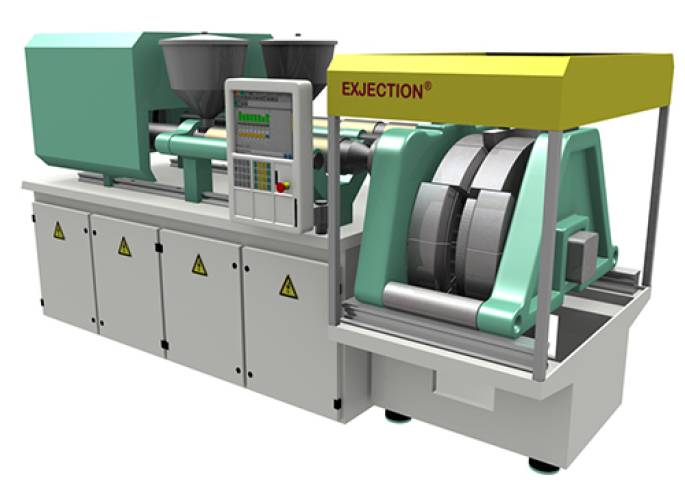

EXJECTION | BASIC

ExM | CONTINUOUS

After the mould has been closed, the EXJECTION process will conventionally start with injection into the cavity.

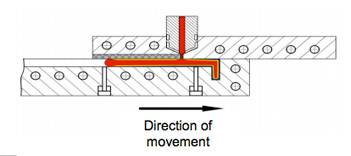

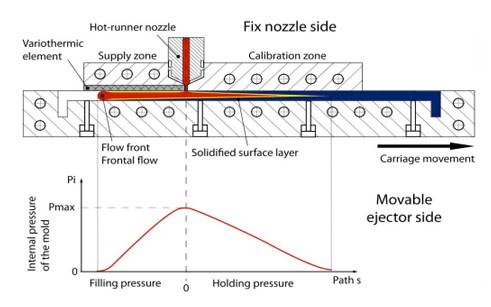

The sledge of the EXJECTION mould is in the initial position. The whole component geometry is moulded into the sledge, the mould cavity being open throughout the length of the first cut. A sword on the fixed nozzle side of the mould will partially seal the mould cavity and acts as an extrusion die with a calibration unit. The molten mass will flow away from the first cut into the open cavity over a hot-channel nozzle and fill the final area.

Even before the molten mass leaves the leading zone, which is approx. 100 mm long, determines mould forming and is heated in a variothermal way, the sledge starts to move against the injection direction. The schematic diagram of the filling process shows this in a section through the die. The injection process will primarily occur in a pressure controlled manner, the velocity of the flowing front and sledge movement being harmonized. This means that the first cut will rush behind the flowing front. Thus it will, at any time, be possible to achieve an injection pressure that is constantly low as well as a stable afterpressure. The latter also is enabled by the balanced cooling-off process. Furthermore, a constant pressure and low shear rates make it possible to fill very long cavities in a balanced manner and without weld lines.

The sledge velocity and injection profile will be controlled over the whole component length by set values and velocity profiles. In this respect, control variables are formed by the cross section of the profile and the component thickness. These variables will, depending on the injection material and the process temperatures, determine the cooling-off velocity and thus the sledge velocity. The thermoplastic molten mass will cool off away from the flowing front on the surface of the mould cavity and is subject to a balanced afterpressure curve until the molten mass is solidified throughout the wall thickness. Depending on the viscosity of the molten mass, filling velocity and thickness of the component wall, filling pressures and thus afterpressures just as well can be chosen in the range between 50 and 300 bar.

After solidification, the extruded surface will leave the calibration zone of the nozzle insert and emerge to the open air. After the first cut has reached the end of the cavity, the sledge will be made to stop while the injection process will be finished by afterpressure. Cooling off, dosing, opening the mould and moving the sledge back to the initial position add up to the overall cycle time of the EXJECTION process. This process corresponds to an injection moulding process with cascaded control at filling from one component end.

Production of endless

injection moulded parts

injection moulded parts

The EXJECTION technology does not stop at the production of products with a length of two or three metres. One of the most exciting further developments of the process, which has been accomplished in the last two years, was aimed at enabling production of endless injection moulded parts. The idea underlying this concept is quite obvious: The shaping cavity will be built from individual segments and with a defined length in a modular manner. This makes it possible to de-mould the sections of the developing component, which flow out of the mould and have already been solidified. The elements of the cavity that are, so to speak, not needed any more will, after de-moulding, be led back to the other end of the mould. There they will form a new empty cavity and can be filled again by the molten mass. This process can be represented as a linear process, which uses circulating strings of moulding elements, or in a rotary design, which uses a rotary table. Here the concept of an EXJECTION facility is visualized by showing an EXJECTION mould that is used to manufacture endless injection moulded parts and has a rotary design.

Increased efficiency and cost savings with EXJECTION

The EXJECTION facilities that have already been implemented make it possible to manufacture very long components at small closing forces. As a comparison with the machines that are otherwise necessary for injection moulding of long components and have closing forces that are much higher, energy consumption can be reduced by approx. 60 % (!) when using EXJECTION. As far as the investment volume is concerned, the average saving potential offered by EXJECTION amounts to about 40 % as compared to conventional injection moulding. This means that the production costs will be made to be 20 % lower by the new process. This corresponds to the success formula of 60 / 40 / 20 for innovative technologies with superior product advantages.