An important issue for future projects is the fact that productiveness of the process and the projects will be increased even more. No unproductive idling times on the machine and simultaneous dosing, injection, cooling off and de-moulding - this is ...

... your FUTURE. This is EXJECTION.

Examples for possible applications and visiones for innovation:

3D Geometries

Manufacturing segmented profiles with real 3D geometry and an open margin as it is already reality in the conventional injection molding.

Overmoulding

Endless production of structured and functionalized hybrid profiles by overmoulding and inserted endless belts.

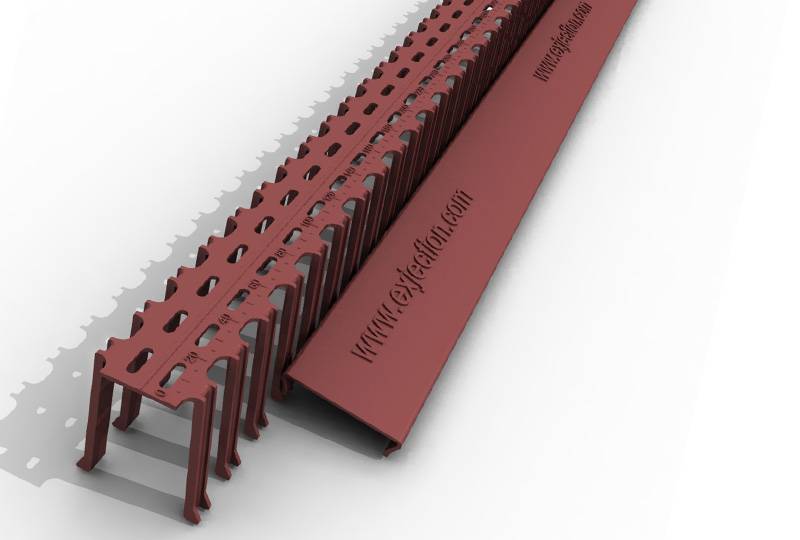

Manufacturing of small parts

The manufacturing of small parts on a roll, positioned on a central strand in conjunction with a simple feeding system for assembly machines.